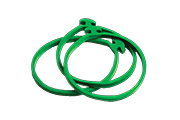

D Profile Gripper Cord for Packaging Machinery

EPDM Industrial Parts

Metal Detectable Anchor Bands

Industrial Silicone Rubber Products

Custom Silicone Solutions by WHsilicone

Silicone rubber stands out as a versatile material renowned for its myriad beneficial properties, including high-temperature performance, transparency, durability, and exceptional electrical insulation. These attributes, among others, position silicone rubber as a highly sought-after material in industrial markets. Whether you require a tailor-made extruded gripper cord for packaging machinery or a custom molded silicone piece for metal-detectable equipment, WHsilicone offers comprehensive services from prototype to production.

Our industrial products primarily utilize materials such as silicone, fluorosilicone, dimethyl silicone, and foam silicone. However, depending on the application, other elastomers such as EPDM and synthetic rubber are also valuable.

We specialize in crafting custom parts for various industrial applications, including:

- “D” profile gripper cords for packaging machinery

- Metal-detectable cords

- U-channels

- Rubber gaskets & seals

- Water system O-rings and hoses

- Tubing

- Grommets

- Belts

- Wire and cable harnesses

Furthermore, we manufacture industrial products designed for extreme environments. These components offer numerous benefits, including:

- Resistances: Silicone's inert nature makes it resistant to most chemicals, ultraviolet radiation, ozone, water, and oil, while also inhibiting mold and fungal growth.

- Dielectric strength: Silicone materials serve as excellent electrical insulators and maintain integrity under typical current exposure.

- High temperature resistance: Most silicone extrusions can withstand temperatures up to 500°F and are flame retardant.

- Elastic memory: Silicone extrusions possess outstanding elastic memory, ensuring they maintain or return to their original shape after exposure to high pressures or compressive forces.

- Transparency: Silicone's relative clarity facilitates easy coloring or use in clear tubing.

At WHsilicone, we take pride in our ability to design custom silicone extrusion products to meet a diverse array of needs. Our manufacturing processes adhere to numerous industry standards, including FDA 26CFR, ISO 9001:2015, ASTM, ITAR, Buy American Act, WOSB, and MIL-STD-105e.

As a leading custom rubber manufacturer based in China, WHsilicone is equipped to formulate custom compounds tailored precisely to your application requirements. We offer product manufacturing in various colors, including PMS color match.

For further insights into our capabilities, please explore some of our case studies. If you're interested in collaborating with us, please request a quote or reach out to us directly.